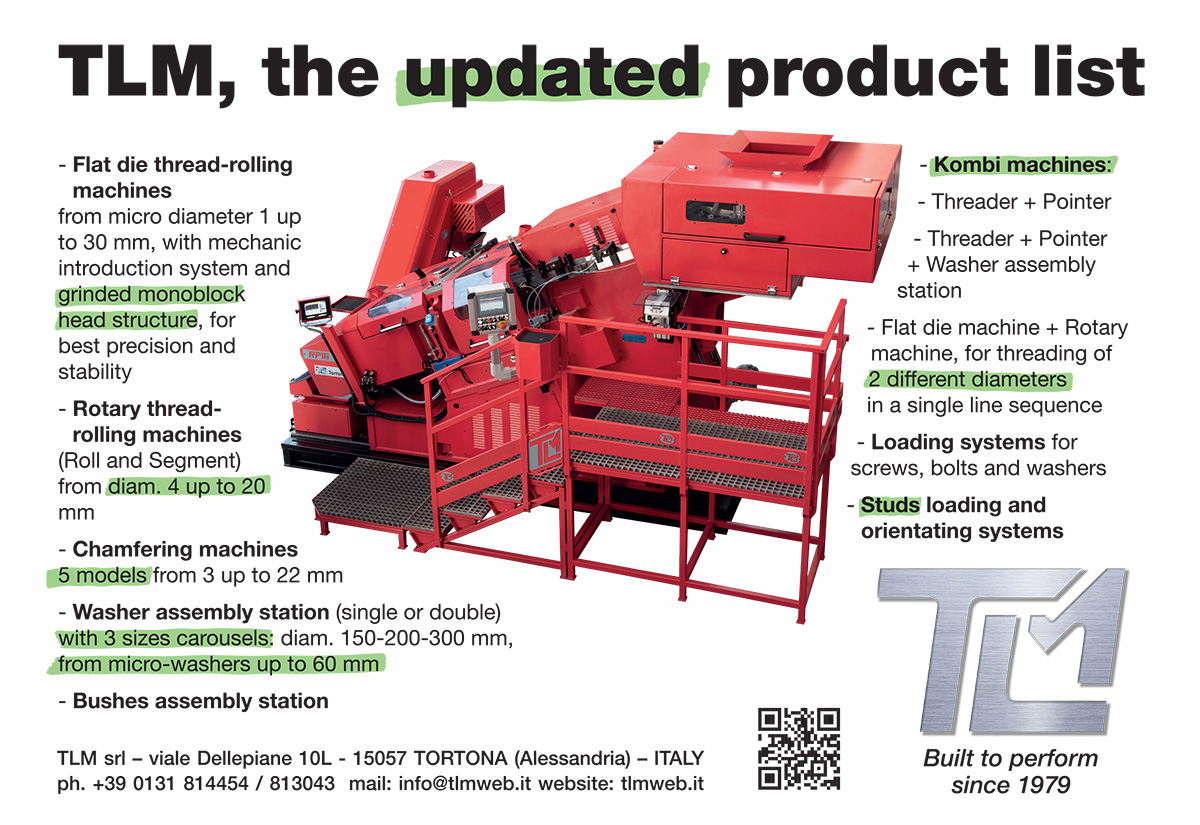

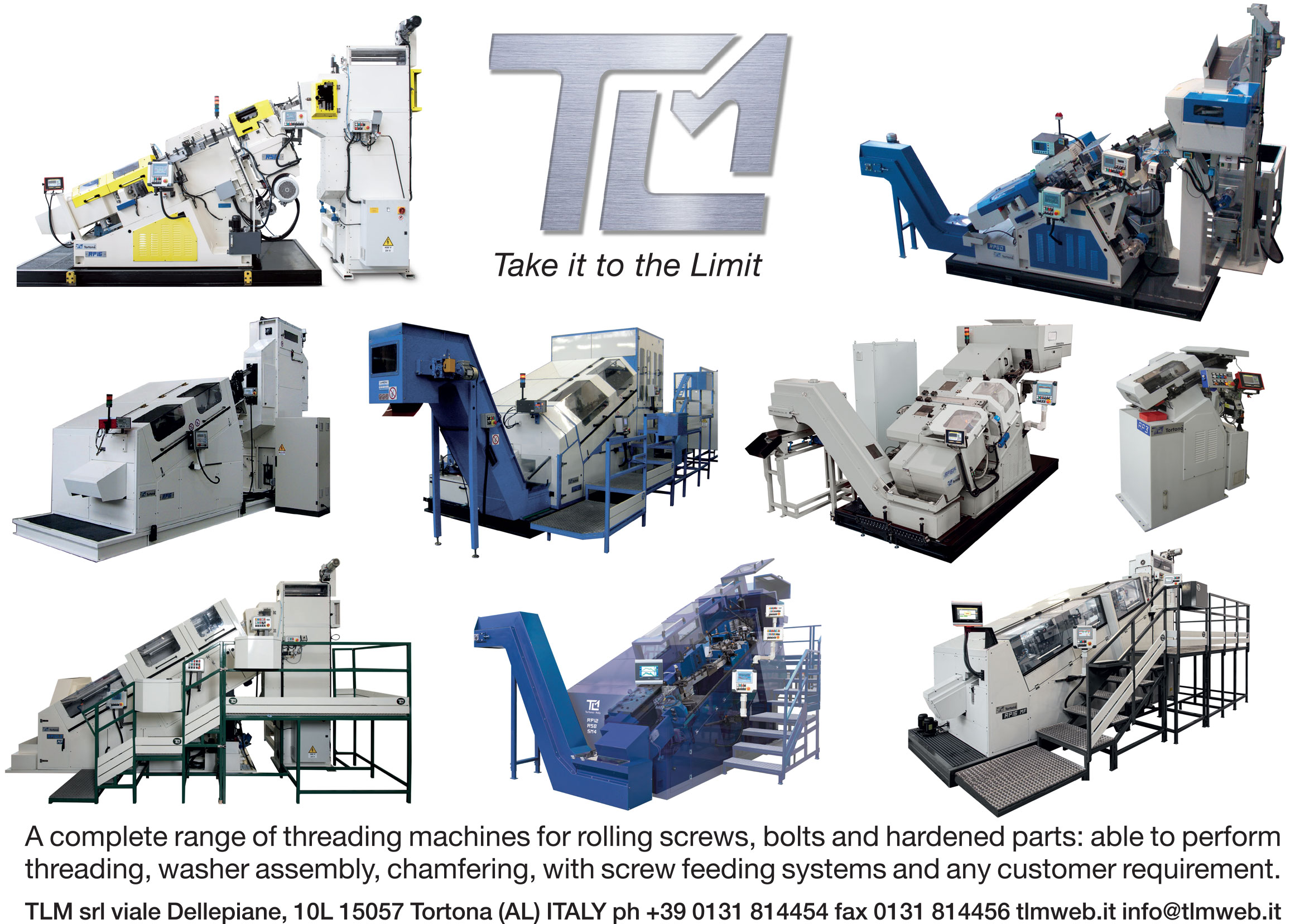

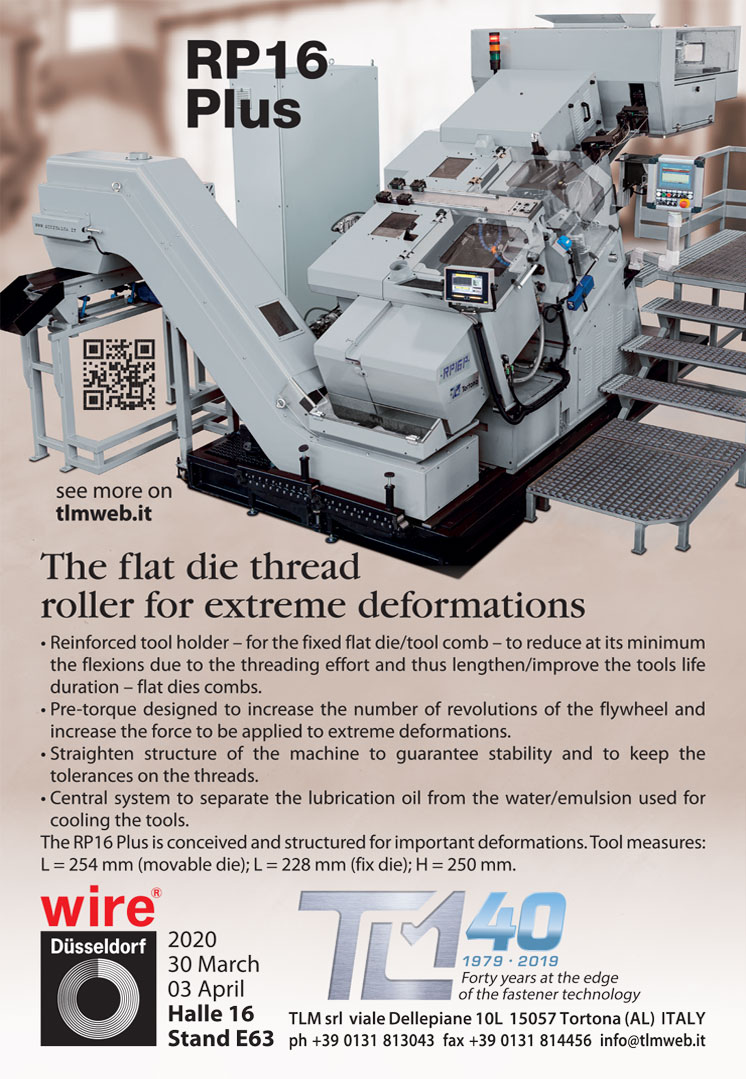

Advertising

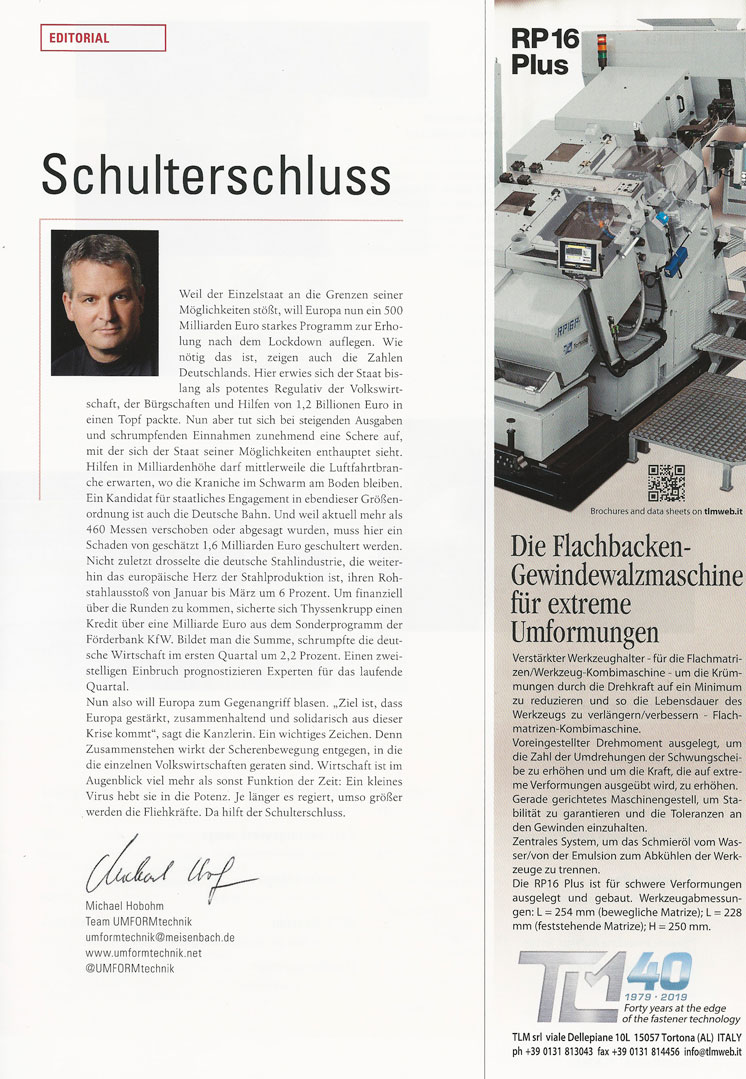

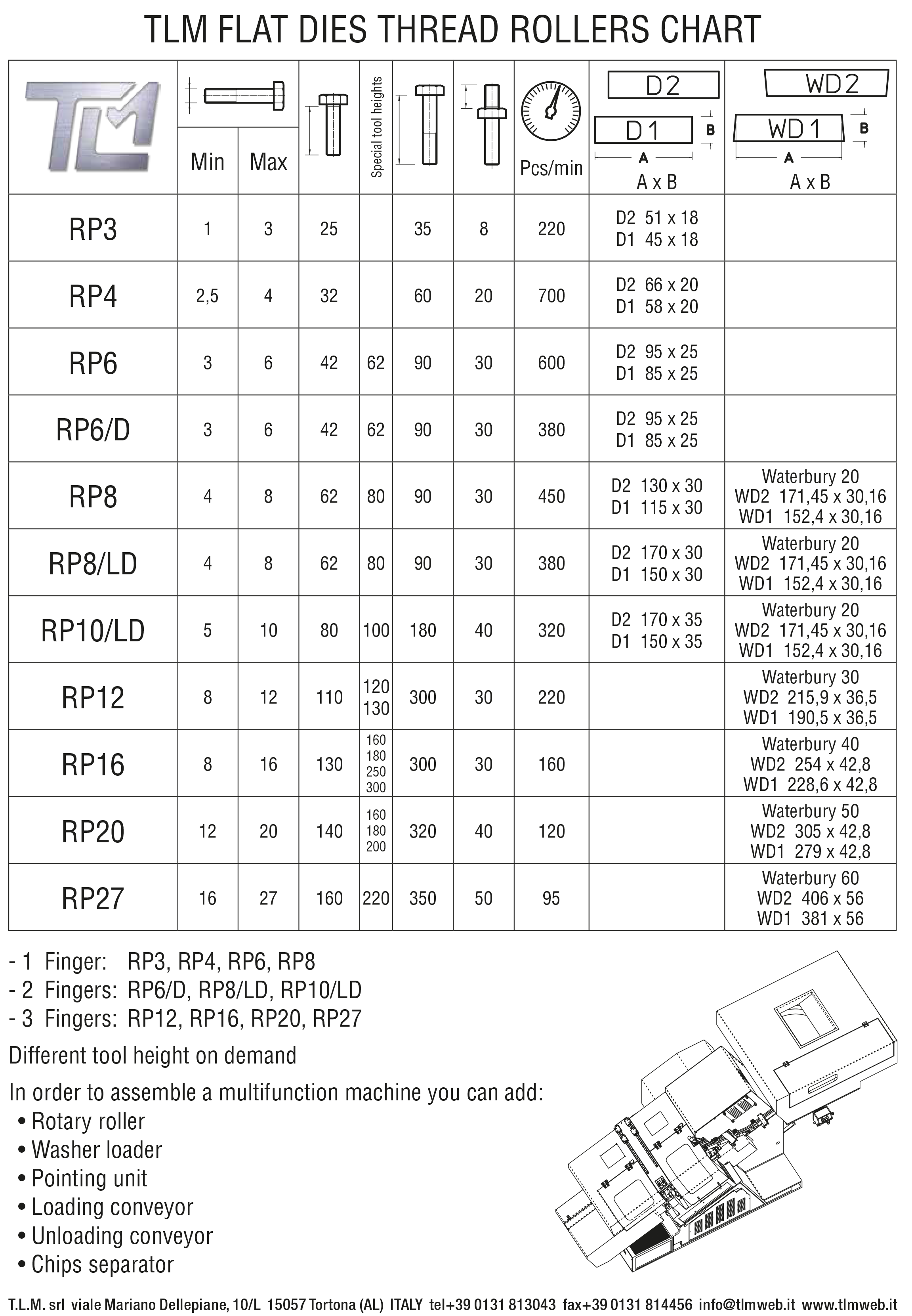

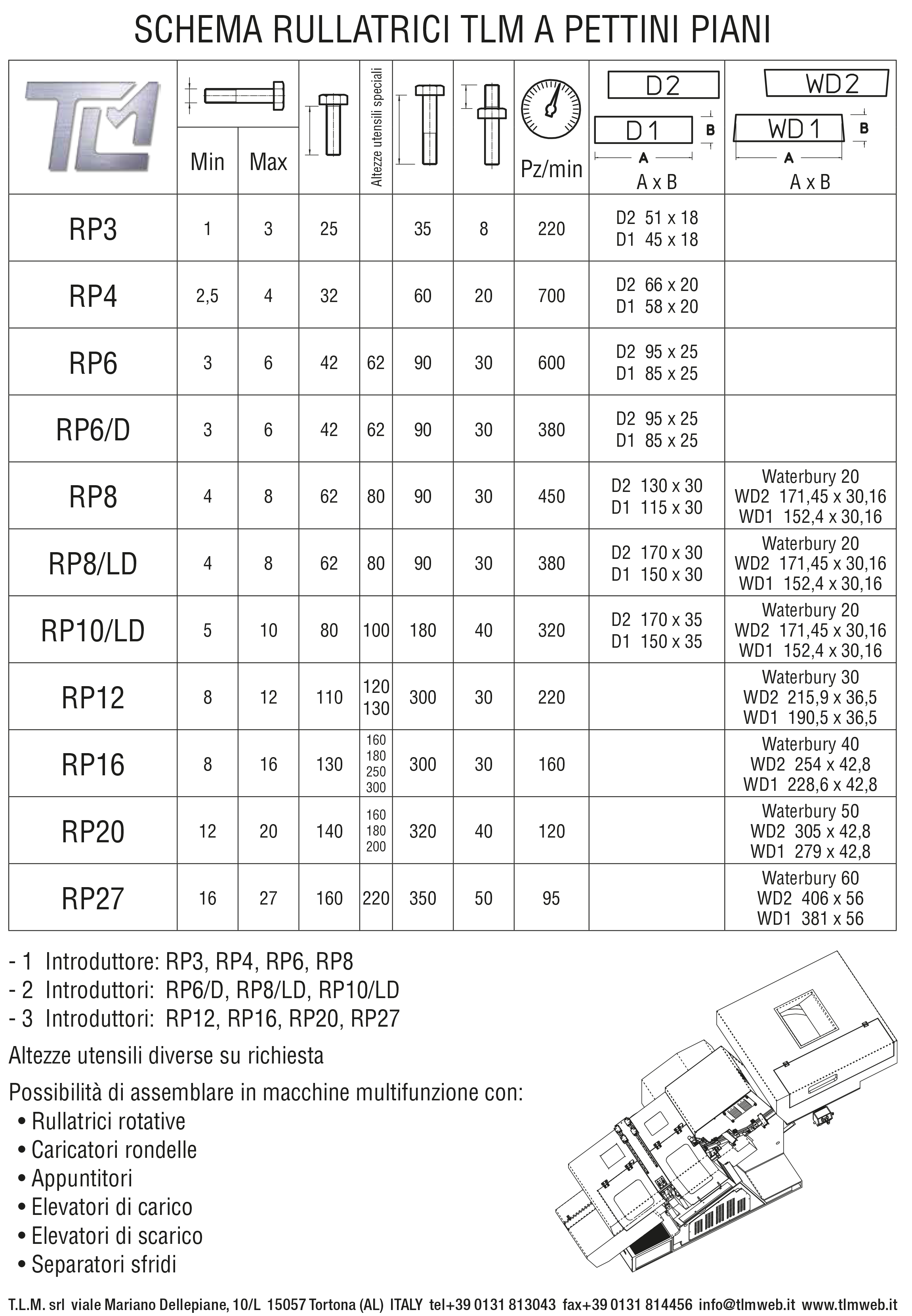

TLM flat dies thread rollers chart

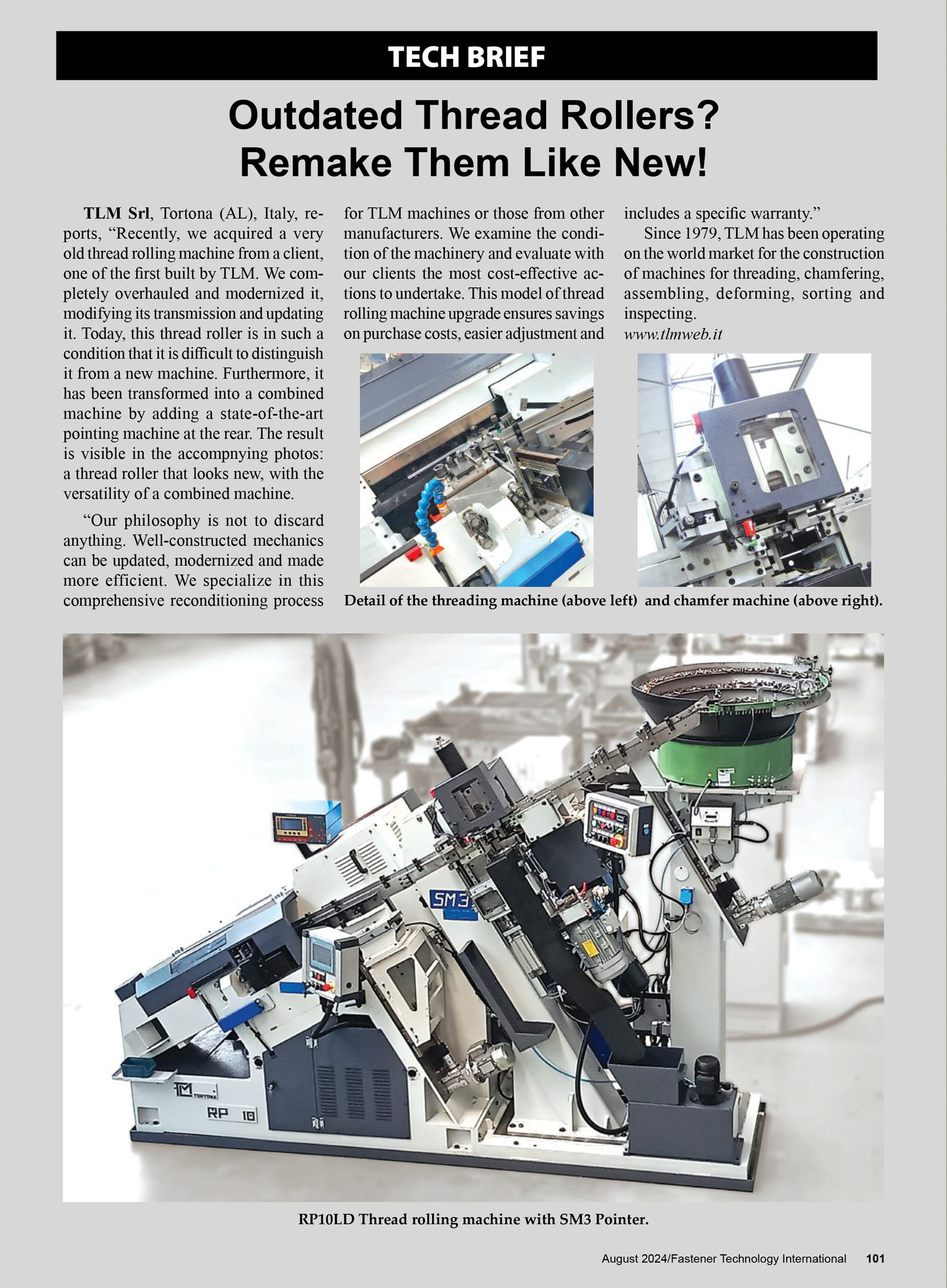

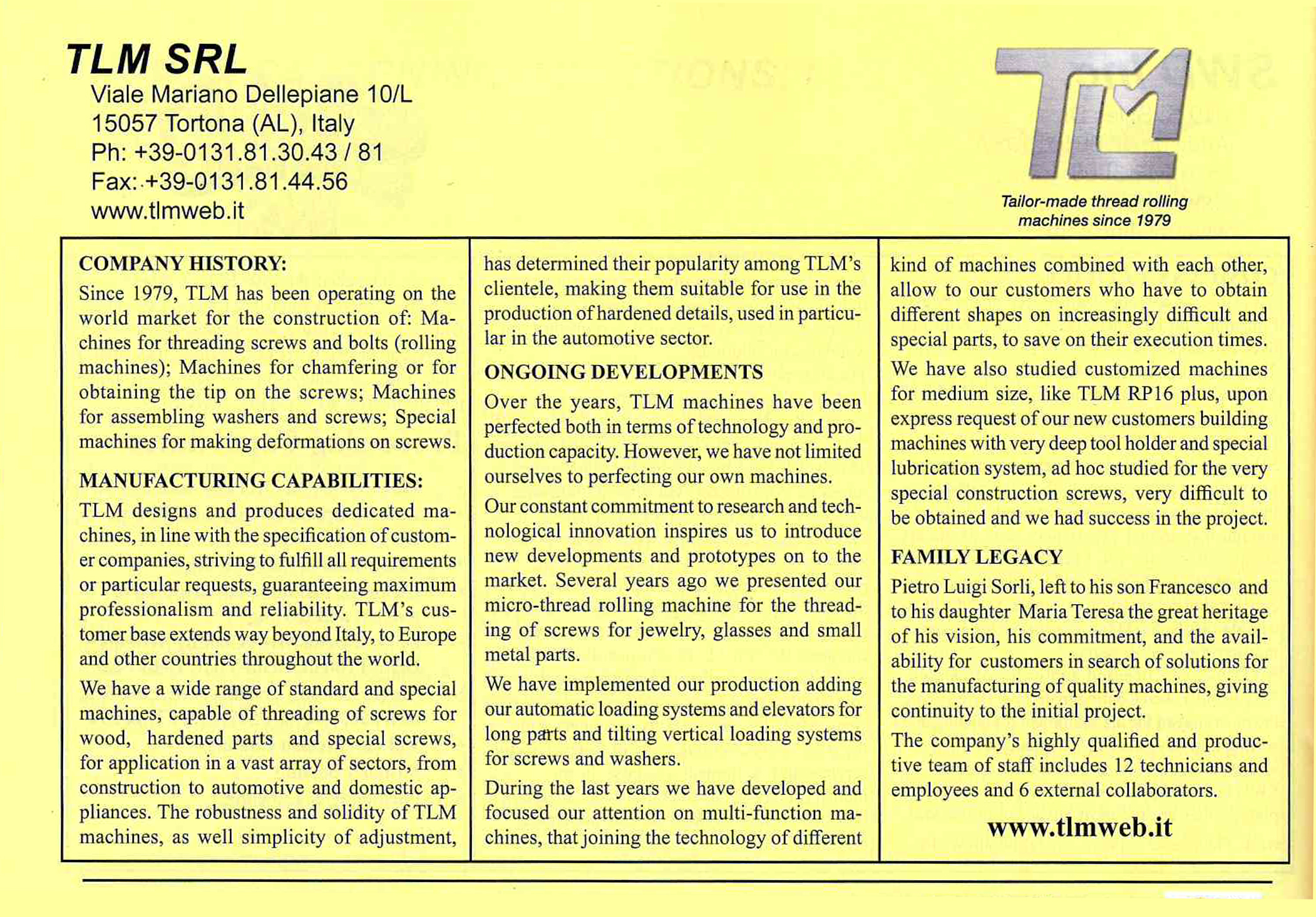

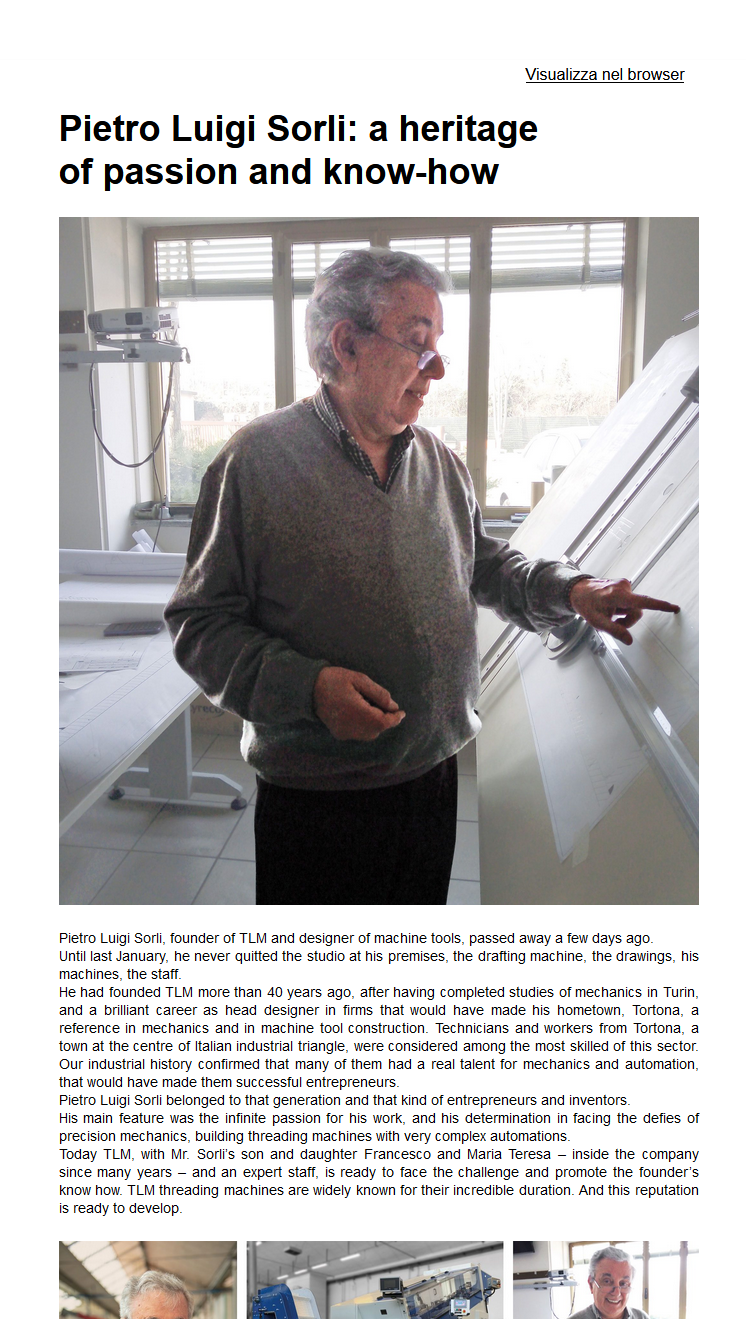

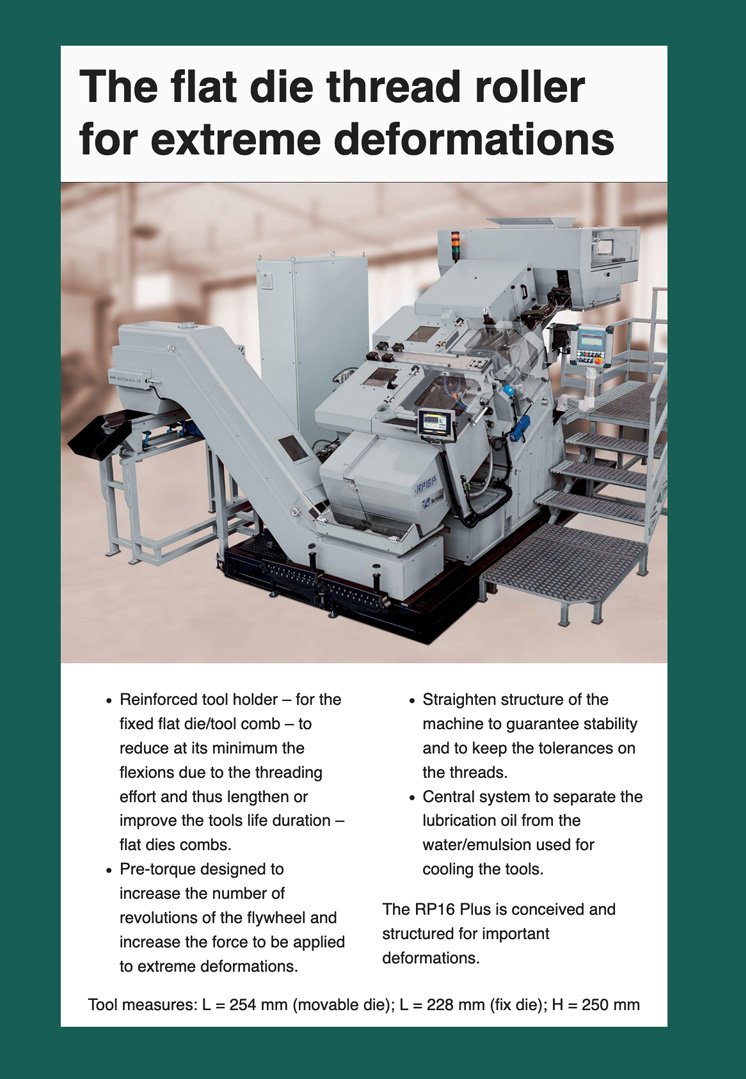

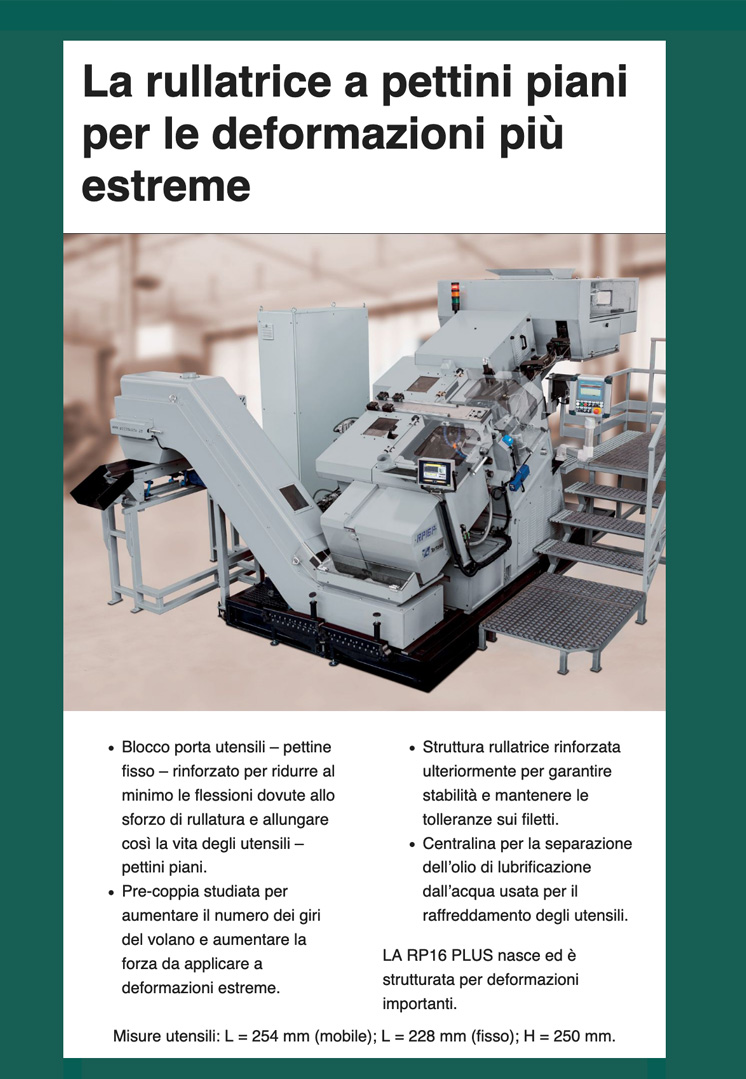

Dal 1979 TLM è protagonista nella progettazione e nella costruzione di macchine per la rullatura di viti e bulloni, per la smussatura o la punta delle viti, per l’assemblaggio viti rondella, di macchine speciali per l’esecuzione di gole e altro. Progettiamo e produciamo automatismi dedicati, su specifiche delle aziende clienti, in Europa e in altri paesi del mondo. Presentiamo una vasta gamma di macchine standard e speciali, in grado di rullare sia viti a legno, sia particolari bonificati e viti speciali, per i più svariati settori, da quello edilizio a quello automobilistico e degli elettrodomestici.

La robustezza, come la semplicità delle regolazioni, hanno determinato il successo delle macchine TLM, oltre a renderne possibile l’utilizzo nella produzione di particolari bonificati, impiegati soprattutto dalla industria automotive. Negli anni le macchine TLM sono state perfezionate sia sul piano tecnologico, sia sulla capacità produttiva.

Siamo costantemente impegnati nella ricerca e nell’innovazione tecnologica, e proponiamo al mercato novità e prototipi. Tra le ultime nate, la microrullatrice per la filettatura di viti per gioielleria, occhiali e minuterie metalliche, la macchina di controllo qualità, e i sistemi di carico automatico o elevatori per particolari lunghi.

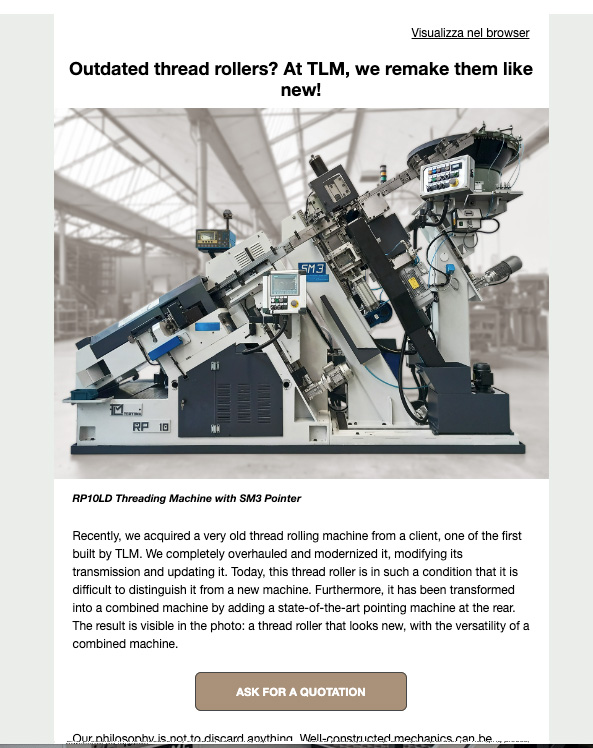

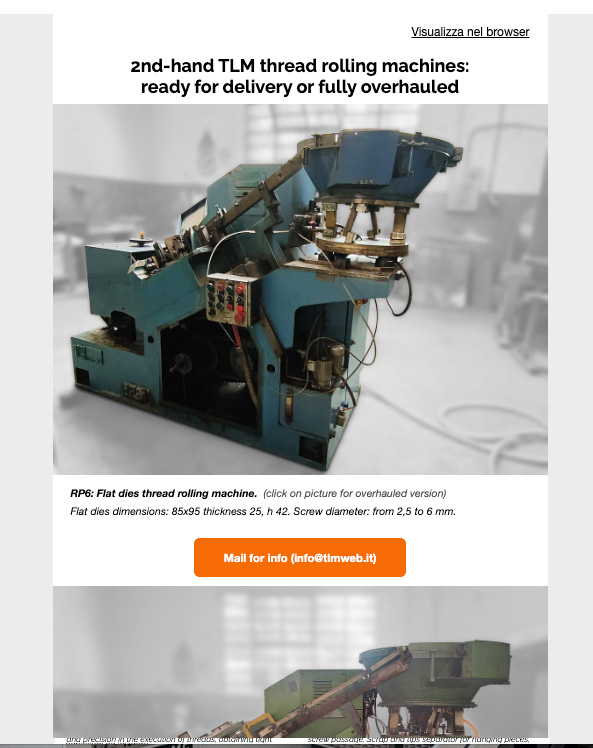

We design and produce dedicated machines in line with the customer specifications,

in Europe and throughout the world. We have a wide range of standard and special machines, capable of rolling wooden screws, hardened details and special screws, for application in a vast array of sectors, from construction to automotive and domestic appliances.

The robustness and solidity of TLM machines, as well as their simplicity of adjustment, has determined their popularity among our clientele, making them suitable for use in the production of hardened details, used in particular in the automotive sector.

Over the years, TLM machines have been perfected both in terms of technology and production capacity. However, we have not limited ourselves to perfecting our own machines.

Our constant commitment to research and technological innovation inspires us to introduce new developments and prototypes onto the market. Our latest creations include: a micro-thread rolling machine for the threading of screws for jewelry, glasses and small metal parts, a quality control machine, an automatic loading systems and elevators for long parts.